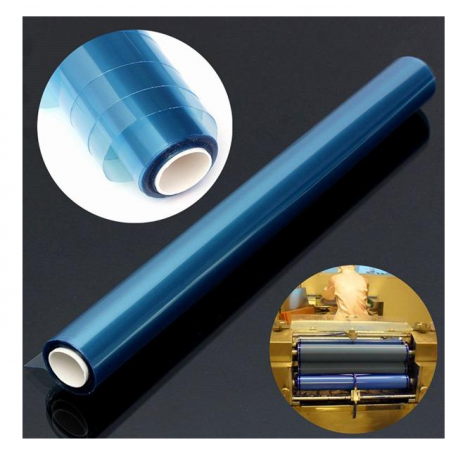

Pelicula Film Fotosensible 30cm X 5 Metros Fabricacion Pcb Fotopolimero Itytarg

10204

Nuevo producto

Este producto ya no está disponible

Más

IMPORTANTE - LEA ATENTAMENTE ANTES DE COMPRAR

ESTE PRODUCTO REQUIERE DE EXPERIENCIA PARA OBTENER RESULTADOS SATISFACTORIOS

EL PRECIO NO INCLUYE LOS QUIMICOS REVELADORES

NO COMPRE EL PRODUCTO SI NO CONOCE SU USO

NO BRINDAMOS ASESORAMIENTO SOBRE ESTE PRODUCTO

FILM FOTOSENSIBLE PARA CIRCUITOS IMPRESOS

Material foto-polímero resistente a los químicos

para grabado de circuitos impresos

Capaz de reproducir fielmente el patrón del circuito

con luz ultra violeta a través de un negativo.

Es posible obtener resultados profesionales en

montaje superficial.

Resultado 100% profesional

VENTAJAS Y ESPECIFICACIONES

Color................................................: azul

Espesor ...........................................:40 micrones

Rango de Exposición.......................:365 a 400 nm

Química ............................................:negativa

Resolución.........................................:0,06 mm

Revelado............................................Solución

Almacenaje:........................................5-21 C, 30-70% HR

Alta definición en la formación de imágenes

Gran adherencia a diversos materiales

Revelado y eliminación fácil y segura ( no tóxico)

Excelente costo beneficio

Condition: New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller's listing for full details. See all condition definitions- opens in a new window or tab ... Read moreabout the condition

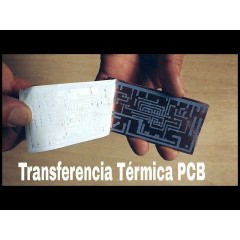

30cm Photosensitive Dry Film Replace Thermal Transfer PCB Board Longth 5M

Feature:

Width: 30cm

Length: 5M

1.5 mil thickness of dry film can be completely cover a hole of 0.25 inches

The dry film can be used in the most ordinary plating solution, no wrinkle, no discoloration

Operating steps:

1, grinding CCL,using the finest polished clean water frosted paper on the line.

2, removing film, photographic film is sandwiched between two layers of film, the first side can make use of transparent tape tear torn, try a few on the line.

3, and then foil, copper clad laminates can look a little cleaner, pasted, try not to have bubbles.

4, good paste membrane used presses, not too hot, about 100 degrees from the fixing.

5, the printed circuit board film, suggestion is to use film, the fine could reach the highest degree of accuracy if you did not ask for the paper to print it with sulfuric acid trip.

6, the printed circuit on the photographic plate (Note: Dry film is negative, so to highlight the print, which we usually use photographic plate opposite) with ordinary energy-saving lamps 10 or so, if there is exposure Machine 1 minutes on the line, the sun not tried, it should be 30 seconds -60 seconds, the exposure process Obviously, since the photosensitive film will change color when exposed to light, the light becomes dark blue. You will easily see your circuit diagram appeared on the board.

7, developing and tear the protective film on the front panel, into the developer (developer according 1:100,10 g Total 1L of water) to be used when developing a little harder stick cotton wipe board.

8, etching, this goes without saying (ferric chloride etchant environmental protection, hydrochloric acid + hydrogen peroxide, etc.) is recommended environmental etching shop, fast, clean, no odor.

9, after a good CCL etching, stripping, from film watered by 1:60 or 70, the board bubble like a few minutes,

10, after the completion of the board, very pretty good, most dense line spacing is 0.1MM, width 0.1MM, 0.1

Ejemplo de uso